KOMATSU-PC400-7/450-7 Carrier Roller Assembly for crawler excavator undercarriage/OEM quality rollers factory in China

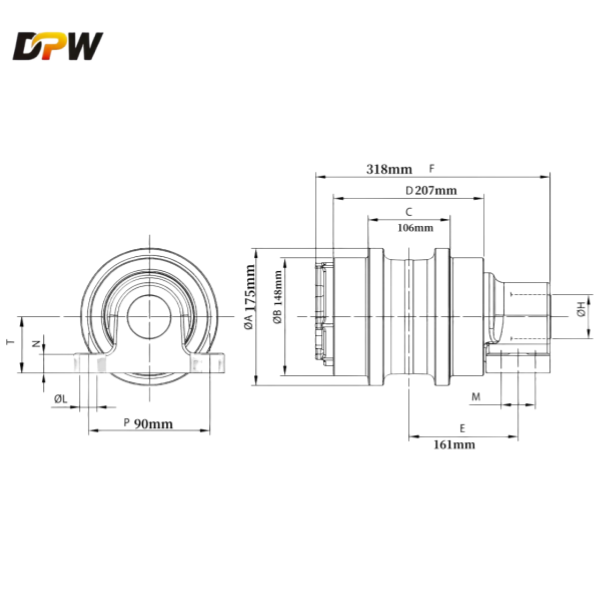

Product Specifications

KOMATSU PC400-7 carrier roller is a critical undercarriage component designed to support the weight of the excavator and guide the track chain during operation. Specifically engineered for the PC400-7 model, this roller ensures smooth track movement, reduces friction, and enhances overall stability and durability in demanding working conditions.

Komatsu PC450 Carrier Roller Specifications

Type: Upper carrier roller (may also be called "top roller" or "track roller")

Compatible Models:

Komatsu PC450-5, PC450-6, PC450-7, PC450-8 (confirm exact model)

Some rollers may also fit similar-size machines like PC400 or PC490 (check part numbers)

Material: High-carbon steel for durability

Sealing: Multi-lip seals to prevent dirt & moisture ingress

Lubrication: Grease-filled (some may be sealed & lubricated for life)

Replacement Options

OEM (Komatsu Genuine Parts) – Best fit & longevity, but higher cost.

Example part numbers:

PC400-5: KM1817 (varies by exact serial number)

PC450-7: Check with Komatsu dealer for latest part 2083000431

High-Quality Aftermarket (DPW PARTS;CQCTRACK) – More affordable, but verify compatibility.

Reconditioned Rollers – Cost-effective if in good condition.

Key Features:

Heavy-Duty Construction: Made from high-quality, wear-resistant materials to withstand harsh environments and prolonged use.

Precision Engineering: Ensures proper alignment of the track chain, minimizing uneven wear and extending undercarriage life.

Sealed & Lubricated: Equipped with advanced sealing technology to prevent dirt, debris, and moisture ingress, maintaining smooth rotation.

Compatibility: Designed specifically for the Komatsu PC400-7 excavator, ensuring optimal fit and performance.

Reduces Ground Pressure: Helps distribute the machine’s weight evenly, improving traction and reducing soil disturbance.

Function:

The carrier roller supports the upper section of the track frame, preventing excessive sagging of the track chain while maintaining proper tension. This contributes to efficient power transmission, reduced vibration, and lower maintenance costs over time.

Applications:

Ideal for construction, mining, quarrying, and earthmoving operations where reliability and longevity are essential.